-

Posts

25 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Joeys Models

-

Shucky I agree with you !00%. People always trying to find cheep ways to build molds. This is fine if you are just casting for yourself. But I see guys trying to sell their stuff. Missing parts of the mold, full of pin holes. Just plain BLAH_BLAH_BLAH_BLAH because the want to cut corners. I believe if they want to step up there quality. They need to step up on their casting methods. Use quality supply's and better mold quality. People stop trying to reinvent the wheel. YouTube is full of videos that show what professional casters do.All I have ever used is a good quality RTV, several different mold releases, and quality resin like Smooth On. Been doing this for 35 years. Never a problem with my castings.

-

Freeman Supplies carry's everything you need. I uses 202 pattern release for two part molds to keep the second pour of rubber from sticking to the first pour. Or you can use Vaseline. And they carry paintable silicon release for the mold. Best to use this for molding as it will not leave silicon behind that you cant wash off but lubs the mold.They also carry Sulfur less Plastisine clay which will work with silicon molds. Will not react to the silicone.

-

Freeman Pattern Supply carries 202 Pattern release and Paintable silicone spray release . I use them for my casting. 202 is basically a Vaseline in a spray can. Used to keep two part molds from sticking together when you pour the second half. Paintable spray release is just that. You can paint the part after you cast them.

-

Do you have masters ready to cast?

Joeys Models replied to GaryR's topic in Car Aftermarket / Resin / 3D Printed

Its is very cast able. But you would have to have the noes piece as a separate piece. Can not pull that body out of a mold with that nose as part of the body. Belly pan would have to be a separate piece too. -

Modelhaus going, going Gone !!!!!!

Joeys Models replied to WoodyRDC's topic in Car Aftermarket / Resin / 3D Printed

Greg Wann can you give me a contact number for Don? I would be interested in his masters and any molds he wants to sell. Email me a jdfoxz2000@yahoo.com -

Should not be a problem. The silicon rubber has a shrink factor to it. Usually .001 to .003 . Worse if it's cheap rubber like Alluminlit. Check their website for spec. on there resin. With painted parts and plated. In my experience will not effect the casting. I usualy prime all my parts before I mold them.

-

NEW PLACE TO GET PARTS CHROME PLATED!

Joeys Models replied to Ben's topic in Car Aftermarket / Resin / 3D Printed

That's true. But Model Chrome is not telling you that on their Facebook .I was just bring up that you have to provide them with a perfect part. They will not do the work for you. I know if you send me a bad part. I will send it back unfinished. -

Refreshing Old Kit Chrome

Joeys Models replied to StevenGuthmiller's topic in Model Building Questions and Answers

Vacuume platting is usually so thin that any rubbing on it will remove it. -

Casting small parts - help

Joeys Models replied to mopargreg's topic in Model Building Questions and Answers

If your only going to do just a few castings. Go to Hobby Lobby and get and Aluminlite casting kit. And use the 40% off coupon to save some money. -

NEW PLACE TO GET PARTS CHROME PLATED!

Joeys Models replied to Ben's topic in Car Aftermarket / Resin / 3D Printed

Rack is only $10. but reusable. -

NEW PLACE TO GET PARTS CHROME PLATED!

Joeys Models replied to Ben's topic in Car Aftermarket / Resin / 3D Printed

12 X 8 flat rate box is $12. -

NEW PLACE TO GET PARTS CHROME PLATED!

Joeys Models replied to Ben's topic in Car Aftermarket / Resin / 3D Printed

Depends on the platter. Me I would use an airbrush. -

NEW PLACE TO GET PARTS CHROME PLATED!

Joeys Models replied to Ben's topic in Car Aftermarket / Resin / 3D Printed

To avoid paying tax's on the business their running. Pay Pal will do the same to you if your doing to many money transfers. They will ask you to do an business account to report to the IRS. -

NEW PLACE TO GET PARTS CHROME PLATED!

Joeys Models replied to Ben's topic in Car Aftermarket / Resin / 3D Printed

This is really not a new process. It’s the same process they use to silver plate mirrors. Centuries old. I just bought a kit. And will soon start doing platting. This is a chemical process not real chrome platting. Thickness depends on how much you apply. About the same thickness as vacuum platting. But what they don’t tell you is that your parts have to be perfectly smooth. Any flaws in the surface will show up. They like me will not finish the parts for you. So I would recommend that you paint a black or very dark blue base coat on your parts. This way you will see the surface shine that you will get back. If it is shinny and no marks. The silver will coat it and shine like chrome. The clear coat is sprayed on it to protect it. An automotive clear urethane is UV protected. It will not turn yellow in time. I don’t know about Model Chrome. But they will tell you that they are not responsible for under surface finish. What you see is what you get. -

Casting resin and air bubbles

Joeys Models replied to Hawk312's topic in Car Aftermarket / Resin / 3D Printed

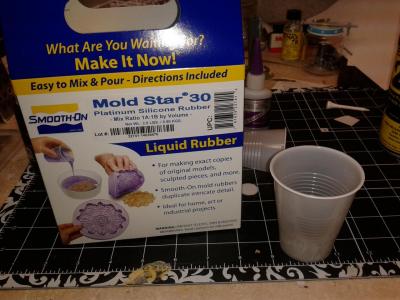

I never have problems with bubbles. I always pressure cast. I mostly do two part molds. Some cheaper resins have a tendency to naturally produce bubbles. Careful, Some resins will foam up when you vacuum. I use Smooth-On products for all my casting needs. -

Anyone do castingsto order?

Joeys Models replied to StreetShaker's topic in Car Aftermarket / Resin / 3D Printed

-

Thats a recipe for a bomb! Dont do it!

-

removing mold release?

Joeys Models replied to lou s's topic in Model Building Questions and Answers

Automotive type greas and wax remover. or Turtule Wax Bug and Tar remover. -

Working with resin/ Primer

Joeys Models replied to my80malibu's topic in Model Building Questions and Answers

I use automotive quality greass and wax remover. 3M is a good brand. But Turtle Wax sells a bug and tar remover at the parts store. Same thing. Removes all wax and sillicon. Just wipe it downd with a well soaked rag. Do this before any sanding is done to you parts. Use it again before you paint. Removes oily finger prints. -

Air bubbles in Alumilite resin

Joeys Models replied to Austin T's topic in Model Building Questions and Answers

I use Smooth On too. The way I make my molds is differt from what others use here. When I pour my molds. its a closed mold. Meanning I pour resin into the mold threw funnels. In the mold has runners and gates. Any area that I see that will trap air. Such as the rim of your wheel. I cut a vent into the mold to have somewere for the air to go out of the mold. I use a peice of .072 stainless steal tubing to punch a small hole into the top half of the mold. It has to bee tubbing. As it goes into the mold. It will cut a small core out of the rubber. I push it all the way threw to the top of the mold. This way the air and resin will flow freely into the mold. Eventhough I use Smooth On 310. It is a no air bubble resin. I still use a pressure pot for curing. no more than 35 psi is need to collaps and bubbles trapped in the mold. Useing this method. I never have any air bubbles. -

Best resin early SBC available?

Joeys Models replied to Jeremy Jon's topic in Car Aftermarket / Resin / 3D Printed

Most early SBC are all the same in outward apperance. Only differences are valve covers and air cleaners. There are many resin castes that sell only the valve coers and air cleaners. The valve covers in the picture you posted are early vett covers. Air cleaner early BB maybe 66 - 68. Kit bash for the engin and find a caster that has the valve covers and air cleaner you need. -

casting resin parts

Joeys Models replied to CrazyGirl's topic in Car Aftermarket / Resin / 3D Printed

Ann here is a cheap way to make mold boxes. I use Glade brand food containers. They come in different sizes and usually cheep. I use them because on the bottom it is marked with the volume of the container. The small round one is about 3 oz and the other is 24 oz. This is helpful in calculating volume for rubber. Also you can just fill it with water and pour it into a cup that you will use to mix your RTV in. I use Smooth-on 1:1 ratio. They have mix cup that have measurement markings on the side! I cut the bottoms of then off. Then invert them and use a hot melt glue gun to glue them down to either a piece of styrene or I use a piece of melamine coated shelving. You can get that at the home centers. Both containers and board are reusable after you pour your rubber. Container will come off the rubber will little problem as it will not stick to the rubber! Just peal off the hot melt and your good to go again. Nice thing about food container is you can get them in different sizes. Joe -

How to fix warped resin body?

Joeys Models replied to nitro_force_fan's topic in Car Aftermarket / Resin / 3D Printed

This may sound crazy. But when I worked in the business. We used to put parts in the oven on a flat cookie sheet at 130 degrees and leave it for a few minuets. All plastic has a memory. So heating it relaxes the plastic and it will return to it’s shape. Pull sheet out and let cool! Try to support parts so they will not collapse. Some times putting them in the sun helps. Just keep and eye on the parts.I have protyps that I cast years ago. I keept then in a suitecase. I opend it up and some of the parts were deformed. I just let them sit in the sun and they went back to their original shape. Joe -

Need Advice From Resin Casters Here

Joeys Models replied to raildogg's topic in Car Aftermarket / Resin / 3D Printed

I have to agree with Art. I myself was into commercial casting. Doing prototype products for the design industry. I used Vaseline exclusively on all two part molds. Never ever had RTV stick together. And It didn’t matter how long I wanted to pour my RTV. The only time I would thin the Vaseline is when I used it close to the part. Otherwise I used it just as it came out of the container. Used a good brush to brush on. Don’t worry if it has brush marks. It will not matter to the mold. Plus like Art said. Its cheep and easy to get! If you get some on the master, don't worry either. You can take a Q-tip and whip it off. Then when you’re ready to pour your second half. Use spray mold release on the master. Then pour. And Richard, all is not lost on your first mold. You can salvage that mold and part. If you have cut it out and did a careful job. What you have created is a book mold. One shop I used to work at. Did these for all their molds. But we used a translucent RTV. We could see into the mold somewhat and cut the mold open. And as far as rubber and urethane. I use Smooth-on. I am just getting back into model making and I am fortunate to live in the Denver area. I can place my order and pick it up locally with out shipping charges. I have found them very helpful. I can call them anytime and get answers. You may have to call the closes dealer to you. Mine is Reynolds Advanced Materials in Denver Colorado. Smooth-on is much cheaper that Aluminite! I went to my local hobby shop and Aluminite kit cost $35. for the RTV. And its only a pound and half. Smooth-on is only $25. Since its is on my way home from work. I just pick it up. Look on Smooth-on web site for a dealer close to you. You can save shipping cost. Joe -

Does he have a website? Can you post a link? Thank you Joe