-

Posts

707 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Texas_3D_Customs

-

Because you can ship a small light package anywhere in the US for five to six dollars with commercial rates if it's really close you'll get down to 4.60 for a small package. And it really doesn't matter where on the other hand UPS you're looking at about $8 for ground service you could use the saver but that just uses USPS for final delivery so you're not really getting that much better video and again it's still about $2 more per package. Now that doesn't sound like a big deal but when you start talking about shipping 100 packages a week that adds up real quick and everybody expects free shipping as well so that's why USPS is usually the default. And then to add insult to injury when you are someone who lives in a remote location like I am there's a surcharge on UPS so for me to deliver to somebody in a remote location and I have to pay them to pick it up you're looking at up to $10 to $15 more per package. So with most of my packages they are anywhere from 3 to 7 oz the difference in prices quite significant and then if the person does live in a rural delivery that price goes up a bunch. I have some customers in Alaska and I can ship USPS for about $5.50 for UPS to deliver that same package via ground is about $17. So that is exactly why breaking down the numbers and everything why USPS is the defacto standard. A lot of people complain about the postal service and I can say that it's not as good as ups but it's not as bad as everybody likes to make it out. When you start delivering as many packages as some of the larger companies it's actually pretty reliable I probably have one package a month that is either lost or damaged and it's insured up to $100 by default now. So far this year I have made six claims so I'm not even at one a month.

-

1960 Ford P/U alternate grilles

Texas_3D_Customs replied to 1st 700 Quad's topic in Truck Aftermarket / Resin / 3D Printed

There's a lens that goes in there it's supposed to fill it out it's probably not perfect -

1960 Ford P/U alternate grilles

Texas_3D_Customs replied to 1st 700 Quad's topic in Truck Aftermarket / Resin / 3D Printed

Just saying -

RA-STI by TX3D

Texas_3D_Customs replied to Texas_3D_Customs's topic in Car Aftermarket / Resin / 3D Printed

Yes he is working on it -

RA-STI by TX3D

Texas_3D_Customs replied to Texas_3D_Customs's topic in Car Aftermarket / Resin / 3D Printed

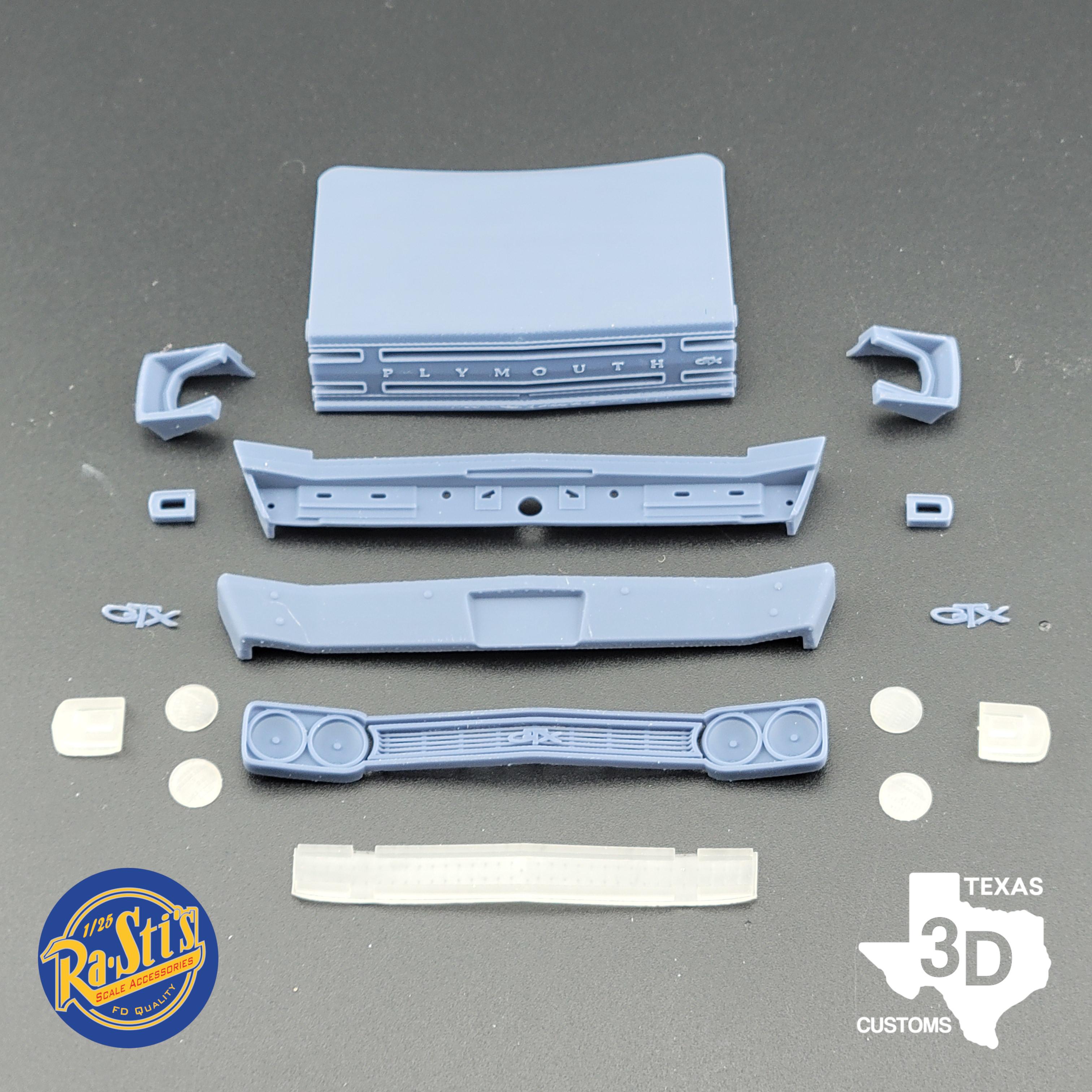

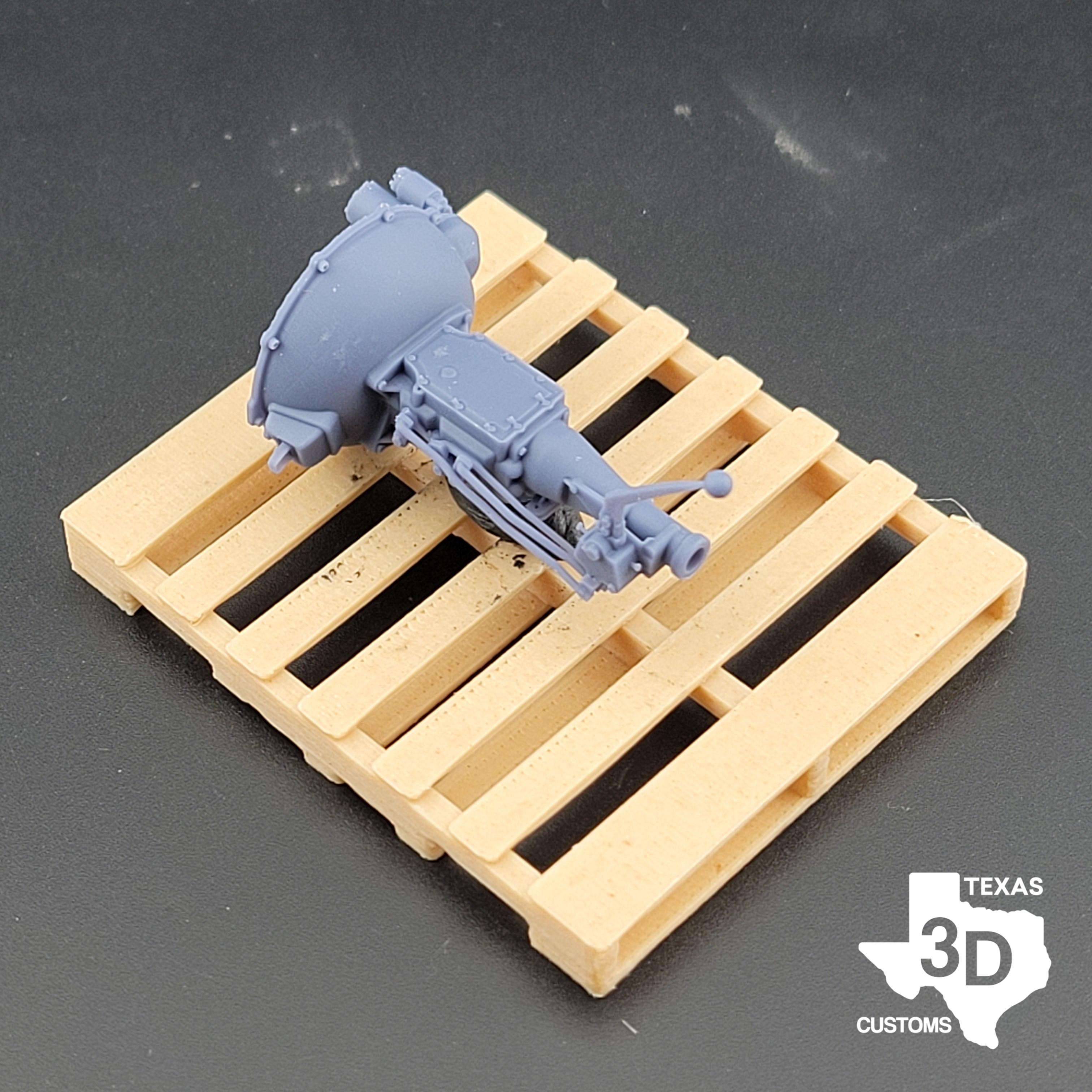

First up is the 1968 GTX trans kit, lots of clear parts lots of small detail. It can be found at https://tx3dcustoms.com/en-au/products/1968-gtx-trans-kit- 7 replies

-

- 12

-

-

Rico and myself have started working together, I see this a great opportunity for both of us. He is gaining a producer of his parts while also gaining access to my scanning equipment and we can co-design items, I am gaining product while also gaining another talented designer to collaborate with. I will be adding his previously available designs to my catalog as I am able to

-

68 GTX grille

Texas_3D_Customs replied to PlymouthFan's topic in Car Aftermarket / Resin / 3D Printed

Yeah I apologize I also have a lot going on still haven't sold my house things are a little hectic right now I did respond to you I'm sure we can work something out -

ISO a '57 Ford F100 Truck Grille

Texas_3D_Customs replied to bobss396's topic in Truck Aftermarket / Resin / 3D Printed

Well I don't look just like the picture you see here -

ISO a '57 Ford F100 Truck Grille

Texas_3D_Customs replied to bobss396's topic in Truck Aftermarket / Resin / 3D Printed

-

Texas 3D Customs

Texas_3D_Customs replied to Erik Smith's topic in Car Aftermarket / Resin / 3D Printed

I've done some more things on my Facebook page and while it does seem like a great idea there are some significant downfalls to it the Pontiac engine I put off for a very long time there were two people who were continuously nagging me about it and I mean relentlessly like I almost kicked him off my Facebook page. And I said fine show me some interest started a whole thread about it no interest at all I mean two or three people maybe cuz there wasn't much really available for it to go in now I did eventually do it 77 trans Am was really easy and I happened to find an engine that I can buy relatively affordably but it made them very very mad that I would not do it even though there was little to no interest. I take suggestions and I listen and most of it comes down to what I think will be a good idea. Now the 1960 F100 I saw it someone said something I was like you know that's probably not a bad idea it has done a lot better than I thought it would and there's only one version out and the comment has been made on my Facebook multiple times I need to do a 58 to 59 and I'm not saying that's out of the realm of possibilities I'm just not talking about what I'm doing but I do listen. -

Texas 3D Customs

Texas_3D_Customs replied to Erik Smith's topic in Car Aftermarket / Resin / 3D Printed

The bigger issue is generally speaking when I do a product line a platform whatever you want to call it there's generally lots of options so I release this 1957 F100 there might be a 58 or 59 a custom there might be all sorts of stuff I will say there are other things coming but I release the first version and it ends up doing really really well and I can't release the next one until I have time to get past the initial surge if I released everything at once I would get behind even more than I am right now I think I've sold close to 30 of these already in 3 days I can only print four at a time without dedicating too many of my printers. Another thing that happens is I'll release one version and nobody buys it because they want to wait to order all of them or whatever so I'm decided to release one wait till I can take the next step if it doesn't do well then I'll release the second one relatively quickly like I did with the Ford Barra engine. But then you have instances like this where if I would have released everything at once I would never even sleep and I need sleep -

Texas 3D Customs

Texas_3D_Customs replied to Erik Smith's topic in Car Aftermarket / Resin / 3D Printed

I am not talking about what I'm doing I have found that that ends up upsetting people when I don't do what they want and if I say that I'm going to do it I don't do it fast enough then that makes people mad so I have this new policy where I don't talk about future plans much. -

Texas 3D Customs

Texas_3D_Customs replied to Erik Smith's topic in Car Aftermarket / Resin / 3D Printed

-

68 GTX grille

Texas_3D_Customs replied to PlymouthFan's topic in Car Aftermarket / Resin / 3D Printed

I don't remember the conversation but that sounds like something I would do you absolutely do not want to put your files online it's a really not fun decision to make but if you are going to commercialize on them putting them out there is the last thing you want to do you will definitely ruffle some feathers and some people will call you names but for the few people who make their own files it makes sense to maintain control of them. -

Odds & Ends you'd Like to See

Texas_3D_Customs replied to Calb56's topic in Car Aftermarket / Resin / 3D Printed

To me quality and accuracy go hand in hand. Without accuracy what is quality? I can release a cone with a bell housing some bolts and a couple of features, thats not quality because its not accurate. -

Odds & Ends you'd Like to See

Texas_3D_Customs replied to Calb56's topic in Car Aftermarket / Resin / 3D Printed

Here is the inherent problem, I am not really sold on just selling bits and pieces, but perhaps a full transmission is possible -

Odds & Ends you'd Like to See

Texas_3D_Customs replied to Calb56's topic in Car Aftermarket / Resin / 3D Printed

Right perhaps I will do a Flathead Muncie using my Flathead and Muncie mashed up. I could also use my Toploader from the FE or Windsor -

Odds & Ends you'd Like to See

Texas_3D_Customs replied to Calb56's topic in Car Aftermarket / Resin / 3D Printed

So I can say that is not even close to an accurate statement -

Odds & Ends you'd Like to See

Texas_3D_Customs replied to Calb56's topic in Car Aftermarket / Resin / 3D Printed

Thats a pretty simple design assuming you have the two mating surfaces figured out. -

Resin will give you the best results hands down, but there are drawbacks and advantages beyond quality. FDM (filament) printers are very finicky but produce more durable parts. Resin printers are easier to maintain and once dialed in are consistent, but they are inherently more brittle and the material is significantly more expensive, especially the more durable resins. There is also the post processing and chemical dangers. I would not recommend an FDM printer for what you are looking for, but they do have their purposes. For reference I have 36 resin printers and 1 filament printer. I have more 3D scanners than I do filament printers.

-

something like that

-

I have no desire to print it again TBH, okay as in its the right shape limited detail and overall more of a Curbside kit

-

I printed that once as I owned an 86, it's okay at best. There is a guy on FB that will probably do it for you. He might be here as well Andy something with an L