4knflyin

Members-

Posts

135 -

Joined

-

Last visited

Previous Fields

-

Are You Human?

Yes

-

Scale I Build

1/12

Contact Methods

-

Website URL

n/a

-

Yahoo

n/a

-

Skype

n/a

-

Facebook

n/a

Profile Information

-

Full Name

Marcus Girrard

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

4knflyin's Achievements

MCM Friend (4/6)

-

Tamiya / Top Studio McLaren MP4/6 1/12

4knflyin replied to JCH's topic in WIP: Other Racing: Road Racing, Land Speed Racers

I thought for sure we would see at least one line in a post where you would grouse about those floor supports. A “well done” must be an order. Took me hours to do only two, and you had to do four! To answer your question, put your glamour shots here (“Under Glass”): https://www.modelcarsmag.com/forums/forum/18-model-cars/ And thanks for answering my questions. I’m more and more convinced that the Calsonic name on the radiators was sponsored by the company for their Japanese home crowd, and that’s why most of the Japanese master builders I’ve seen have painted on their model’s radiators. I’m surprised nobody else has weighed in on that. Cheers. -

Tamiya / Top Studio McLaren MP4/6 1/12

4knflyin replied to JCH's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Come to think of it, I don't know that I've ever seen a pic of a live one with the logo stenciled on the radiators! It's always advanced modelers' kit builds where I've seen it and, for some reason, most of them figure out a way to make a stencil and paint it on. One even said that Tamiya's "Sky Blue" acrylic is an excellent match for color... so I ordered some and it sits unopened for lo all these months (closer to a year). The reference book that came with the kit I bought is the MFH one. It's a different radiator all together, I think. That's a question for you. Take a look. They don't look like the Calsonic ones with the dividing line in the frame that Tamiya chose for their molds, unless there's something I'm missing about how they're configured. Maybe it was only the Japanese GP and it was a nod to the locals? From MFH (unfortunately, the book is all of a car at the Motega (I think) F1 museum. No on-track or other contemporary shots.): Since you're already past this point, can I ask you about this, basically the same qu. as before: these instructions from the TS master detail kit that you have been living for months, look like something that might cause me to pause while I try to figure out what they want me to do — all but one of the steps shows the dividing line on the radiator, but #8 looks like the photos from the MFH book. Why the difference, if it's not just a mistaken drawing? I actually have had a 3D printer for around 8 months but haven't set it up. My hearts not in it, I really wanted a mill except there were so many choices and I had no idea of what to buy for the steep price, which as of today is going to be even steeper. (Edit: oops, I think CH tariffs are on hold pending talks. Can't say for sure, but I may still have a window.) -

Tamiya / Top Studio McLaren MP4/6 1/12

4knflyin replied to JCH's topic in WIP: Other Racing: Road Racing, Land Speed Racers

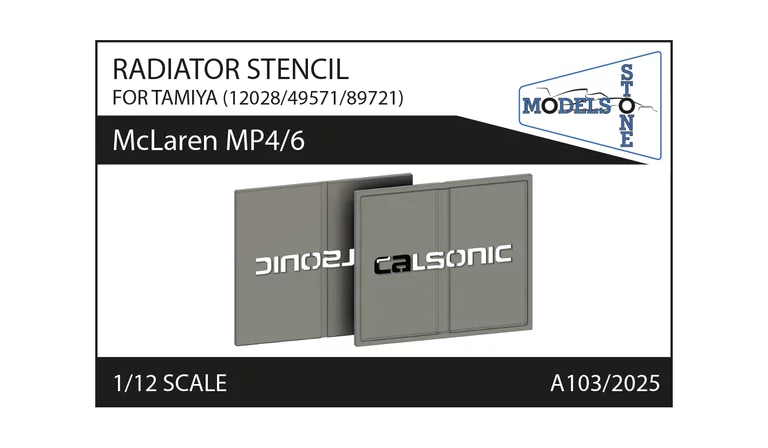

I’ve been happily following along. Very nice… very, very nice. Luckily for us, crossposting is not a no-no. I don’t know if you already have a product in mind, but this caught my eye last week and looks really promising. Pics are from the manufacturer’s site . Spot Model lists it as “just announced,” so who knows when it will actually hit the market (if it hasn’t already somewhere else!). Embarrassing anecdote: I have this kit… and the F190. Both have the metal wishbones, both of which I’ve inspected a few times. Then, recently, I asked a question of a fellow modeler that clearly demonstrated I had forgotten they are metal. Maybe when I start my next kit I’ll try your color coding method. It’s getting worse by the day 🙁 -

1/12 Mclaren MP4/6

4knflyin replied to okazaki0511's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Yes, of course they do. And I know that! Just another of my increasingly frequent brain farts. Thank you for the clarification. -

1/12 Mclaren MP4/6

4knflyin replied to okazaki0511's topic in WIP: Other Racing: Road Racing, Land Speed Racers

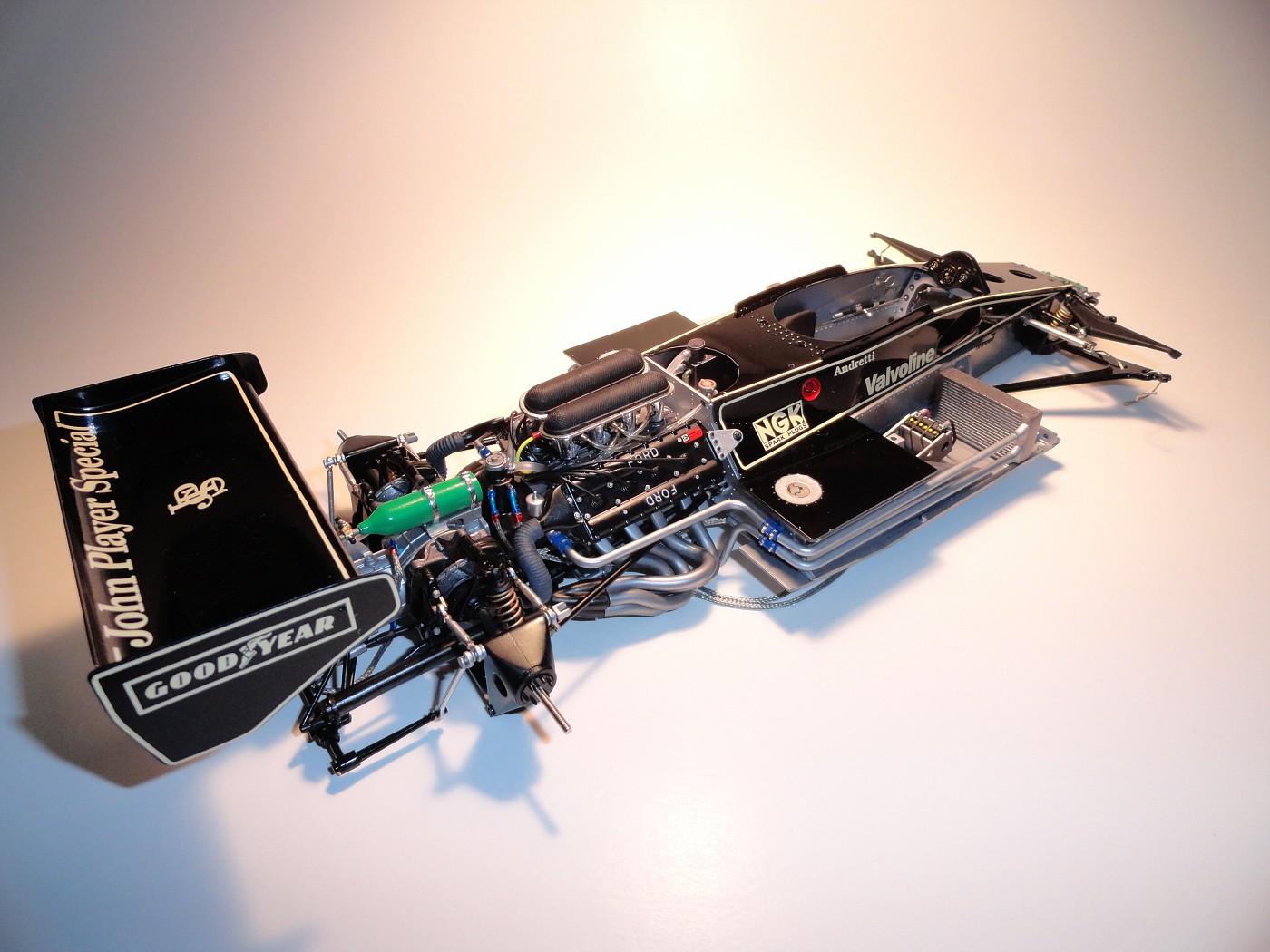

Exquisite, as usual. Among your other refined skills, your ability to use accent coatings so subtly makes all the difference. I love it. Also: you didn’t say, but since you were using the Top Studio up kit, I assumed this was the Tamiya kit. However, the wishbones in the last picture look like white metal to me, and you mentioned MFH, so now I’m confused. -

4knflyin started following I can't get this clear epoxy resin to be... clear , Tamiya / Top Studio McLaren MP4/6 1/12 , Fujimi Fina McLaren F1 GTR Long Tail and 3 others

-

Fujimi Fina McLaren F1 GTR Long Tail

4knflyin replied to Nacho Z's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Agreed, it is gorgeous! And the way you did those windows, paying heightened attention there, really did pay big dividends. After the yellow Harrods GTR livery, this is my favorite. Yet what do I have in my stash? The attention grabbing, can’t take your eyes off it, Ueno Clinic gray on gray with silvery gray highlights… my least favorite GTR livery. A few months ago, Spot Model erroneously started advertising pre-order for the MFH 1:12 Fina and I added it to my notifications. And then it disappeared… without notification. “Sorry, not sorry.” Great work on this, as usual! -

I do have some questions/comments re: the feedback: Brian, "paint tester body forms." That's a new one on me. I think it's a suggestion I can't afford to pass up. About your painting suggestion, are we talking thin coats allowed hours or days to dry, or just a five-minutes between sort of thing? Laski decals? Misspelled, out of business, or could you give me a link? Thanks. Oh, you have no idea. The only parts removed that didn't fall off are the contents of the equipment bays. Even the engine came loose by itself. Otherwise, I'm working on a completed kit. Worse, the plastic has been uncoated and exposed for 45 years. I'm afraid that if I pry at an important part, I may not have much to work with afterward. Truth. And the plastic is rotted. It took me a good six weeks to realize that the "scratches" showing through the paint and some other "painting defects" were actually the plastic underneath. It's falling apart and cracking. Some pieces I stopped perfecting because the were breaking. Even sanding that ancient bare plastic was a mistake. #600 didn't sand it, it clawed it. And no matter how far I went up the ladder of grits, and no matter how many added layers of primer and paint I through at it, those claw marks still show through. Also, thanks for all your contributions. You're a good read.

-

Hey guys, thanks very much. I just logged on to include a couple photos of other peoples' work on this same kit as a way of maybe getting some feedback... only to find great feedback (though not good news) was already here and the problem was my notifications settings somehow got reset. Again, Thanks! Now that I feel comfortable that I know what can be known about it, my solution after reading your input is to sand just enough to make it sort of passable, avoiding the space between the rivets entirely. Clear coating is a '?." I don't know if I have what it takes to deal with any more coatings on this one. The decanted TS-14 is extremely smooth once attended to, and sometimes right out of the airbrush, so it shouldn't hinder decaling by omitting a coat of clear. The rivets that stand out in the pictures I posted are 0.5 mm lead "solder balls." If you think it's easy to mistakenly damage or destroy a molded rivet with errant sandpaper, try running a sheet across lead rivet. (To do the balls as rivets: I made a tool out of a bamboo toothpick to pick them up and place them. I timed the process, not included drilling the holes, and it took 32 minutes to place 63 solder balls. I figure, including drilling at the locations of the existing molded rivets and the need to make a replacement tool along the way, it's a manageable 2.5 - 4 hrs. Also, the jagged line in front of the emergency access is not an error.) I'm going to include the photos of the other builds. One is from John B. here ("Nacho"), and the other a polish guy. Both are from over a decade ago. The great finish they produce is easier to see on the Polish guys work, the second and third photos. I convinced myself they were carefully sanded and polished, but it may just be my lack of an experience-produced critical eye: It was hard to pick a photo from this guys gallery. I chose this one because it shows the side and tops of the cockpit. In particular, it shows the the tricky area to sand in front of the shifter bump out, and also clearly the rivets on the top of the cockpit. This is a bonus pic. Included because it focuses on the area I focused on in my original post.

-

I really want to put this project to bed. I've been working on refinishing the body/chassis of a Lotus 78 build from decades ago. Not having a method for sanding around the rivets has resulted in costly setbacks because I've had to paint and repaint so many times. I'd like this last repaint to be the last, and that's going to require help. How do you do it? Is it just a matter of getting the the paint down in a with a degree of precision that can pass without sanding? Seeing a couple of other builds of this same kit, Tamiya's 1:12 Lotus 78, and the splendid finishes on them, I hardly think that can be it. This isn't the first time I've wanted to know how to do it. And like all the other times when, whether out of idle curiosity or when I was just a boy building airplane models (when, as I recall, all the rivets were raised) I've wanted to know how to deal with sanding and finishing a model with raised rivets without sanding them out of existence, my searches have come up empty. I'm and I'm afraid I may go to the grave without ever pulling it off 😭 (it's just so sad). A couple of pics of an area of the body that I just last week had to finally replace rivets on because I needed to sand the surface in a way that I couldn't save the originals. I'm hoping the first pic makes clear the need to sand... or whatever it is that I haven't figured out!

-

Great minds think alike? I had already started using ice cold water to rinse between grindings. Decided I would try sticking it in the freezer and holding it against some frozen peas to keep it cold — and hopefully solid — while I worked on it. I couldn't help but notice long ago that just holding thin epoxy resin casting for any length of time transfer enough heat from my fingers to turn it rubbery. When I saw your replies, I decided I needed to try my plan before replying back. So I did it and it was noticeably, but only slightly, better. Mike, I checked out the Createx Clear Acrylic and I'm not sure I understand. You put clear coat in your molds to make castings? Or did you mean to mention this Createx product ($$$): https://sculpturesupply.com/products/epoxacast-690-clear That stuff looks like the ticket. Does anybody have experience with it they want to share with us? For that kind of money (and I haven't even checked on the shipping), it would be nice to have more info, even if it was a vastly different application, before I do an experiment with it. I almost forgot to mention, thanks for turning me on to that website. Thats a lot of stuff they've got going on that could be useful.

-

I could have answered this right away because each time I rinsed it between sanding grits it amazed me how the water spots were crystal clear. I have some Alclad Klear Coat that it says can be used for dipping. I've tested it, but on a part that wasn't representative of something like this. Hopefully to save me some grief, how do you deal with keeping the dipping solution from pooling along the edges? Anybody? Here's some evidence: Held above the water. And submersed (this kind of says it all).

-

I've spent at least two hours over the past two evenings. Last night I started with #600, then #1000 and each whole 1000 until after #9000, where's there's a gap in the sanding sticks I use until #12,000. I started it over again last night and got to #4000, which is where I started tonight. Did the rest of the routine, plus Tamiya Coarse through Finish, and ended with Meguiar's Ultimate. The polishes were applied with a Dremel tool on the lowest setting (which is still pretty fast). The material is Janchun epoxy resin. They practically have a monopoly on Amazon. Importantly, the 'glass' started out perfectly clear straight from the mold. There were two significant "air-holes" that I had to fill, hence the sanding. This is the back window on my 959 build, where nothing, but nothing, comes easy. I hope you can help. (The deep scratches have me scratching my head, but I want to focus on the milkyness.) Here's an example of another part I cast with the same resin on the same day, Monday, I believe. These are pictues of the window starting after #12000 through to Meguiar's. This is after the #12000 sanding: After Tamiya Coarse (about 2 or 3 min. per side): After Fine: After Finish: And finally, an hour later, this is what it looks like now after using Meguiar's Ultimate

-

Another of the ubiquitous Tamiya 1:24 "Porsche 959"

4knflyin replied to 4knflyin's topic in WIP: Model Cars

Thanks for saying that, not just because it's nice, but you are giving me an entrée to feed my ego. I read your 959 thread, and Kurts, too. I wish I had his patience — and skill — to make a couple intercoolers. Now for my starving ego: that engine cover got hours and hours of my attention. With each repainting and the changes to gaps that causes, I maintained my goal with that thing: I added the gap, not by just raising the deck, but by sanding what is actually almost a flat line from where it meats the fender skirt up and over the sharp peak. And more important to me than the gap was maintaining the sheet metal (reinforced fibre, I believe) curves that are complex back there, complex and beautiful. At each stage that I took photos of the car, I always included one showed that unbroken flow. If I you didn't give me an opportunity to tell you about it ad nauseum, nobody would have noticed. Still, not many, if any, will get it. Hah! And the opening under the spoiler. Damn. About 30 sec. of careless sanding in that tunnel resulted in my having changed the shape of the semicircle at either end. Than 30 sec. cost me 10 hrs. or more of body repair work. If anybody knows what the pink polyester putty it is that lots of builders are using, please, please post it here. Thanks. Now I'm going to show you stuff that only I think warrants this much attention! It started out innocently enough. Just a bit of light sanding since I was repainting it anyways. Then started big investment of pride in the outcome. Not to mention the big investment of time in "care and feeding" of the beast. Subtle use of Tamiya epoxy putty, which I found oddly soothing to maticulassly feather it to blend with the body. But fixing that 30 sec. of damage to the tunnel, that was not soothing, relaxing, or anything else pleasant. Many very frustrating hours into it, I figured I just wasn't going to be able effectively sand in those corners. And then a eureka moment that lead to results way better than I was expecting, though leaving lots of room for justified criticism from the highly skilled. What you saw there took a long time to do. Tens of hours in all tolled, I'm pretty sure, on just the engine cover/spoiler/fender meeting point. Mathias, you almost certainly get it. It has beautiful lines. -

Another of the ubiquitous Tamiya 1:24 "Porsche 959"

4knflyin replied to 4knflyin's topic in WIP: Model Cars

Great screen name, m’lord. Wow, John, you’ve got a great memory, especially for someone who hasn’t even built the kit. Yes, I’ve read the stories. We shall see!

(1).png.197f04d299468da5445f4f2eb807b16b.png)

(1).png.8942c62bb3251f5c58c61cdb25b2caa2.png)

(1).png.29c074099d7eb4a11c703a5e8233464d.png)

(1).png.a03eeab1e78f6019f76a99fb502a5d39.png)

(1).png.7a8cf8c5e0fe646d20355edb043364a2.png)

.jpeg.92b90faf7a37b02f570f93741bc48208.jpeg)