Art Anderson

Members-

Posts

5,052 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Art Anderson

-

More than likely due to USPS using FedEx for ordinary parcel delivery. Ordered some paint from Scale Finishes a year or so ago: The parcel went from Salt Lake City to Denver, then back to Salt Lake City, then to Denver once again--that repeated itself daily for a week or more, then finally to St. Louis, then to Memphis TN, to Indianapolis IN (65 miles SE of me), then back to Memphis--then back to St Louis AGAIN. Finally I quit tracking it, and guess what, the parcel showed up the day after I stopped tracking it, and who delivered it? FEDEX! (Go figure, huh?) Art

-

Murphy was right!

Art Anderson replied to Oldcarfan27's topic in General Automotive Talk (Trucks and Cars)

When I carefully research the firing order, wire the engine, and some "expert" decides to insist to me that it's all wrong (so then, I wire up a V8 at random, not caring about the firing order, only to have another expert compliment me for getting it right?) What's a modeler to do, huh? Art -

And Ron, as a teenager (Pactra 'Namel rattle cans came on the market when I was 14!) I used to spray paint in our furnace room--old fashioned coal furnace, but never bothered to care about the potential for an explosion!), and while Dad would go "harrrumph!). Mom never said a single word, for as long as I got my grades in school, she approved of every model car I built back then! Art

-

As a boy (way back in the dark ages known as the 1950's), I loved the smell of Pactra or Testors paints, and while I am sure my Mom didn't, she was the single biggest booster of my model car hobby--she NEVER complained about it, not one bit! Art

-

Mold release for making two-piece molds is as close as your medicine cabinet--for over a decade of commercially casting in resin, making 2-part RTV rubber molds, the most foolproof mold-making barrier, and the cheapest, which I used exclusively. ordinary Vaseline Petroleum Jelly, which I added to a 4-oz bottle of ordinary enamel thinner, to make my own mold-release in order to keep the second pour (the inner core of a mold) from adhering to the first (cavity side of the mold) pour. Worked without fail every time. Art

-

What's going on with the rubber

Art Anderson replied to JohnU's topic in Model Building Questions and Answers

Interesting, that given my once-frequent visits to AMT's Maple Road plant, their PVC (NOT RUBBER, BTW, save for their Authentic Model Turnpike cars, which had molded rubber tires for traction), every time I walked past their injection-molder that produced a constant stream of tires, never once did I see anyone use any mold release with that tooling--in fact, the machine was set to a relatively fast cycle, with a fresh batch of tires being popped every 2-3 minutes or so, with nary anyone even monitoring--like it was on "automatic pilot". That almost "oily" stuff that leached out of many of those older tires back then, was PVC Monomer, which use became severely reduced with the great PVC-Monomer "Cancer" scare of 1976-77. Art -

Identifying parts through sprue numbers

Art Anderson replied to ewetwo's topic in Model Building Questions and Answers

Interesting, given that AMT's 34 Ford pickup kit and their Deuce kits are completely different tools--the only shared parts were the tires. Art -

Birth Year for model cars ?

Art Anderson replied to gtx6970's topic in General Automotive Talk (Trucks and Cars)

-

When I was doing All American Models, I simply used Vaseline petroleum jelly, about 1/4 tsp of that to a 4oz jar of ordinary enamel thinner--to coat the cavity and top surface of the first half of my molds, worked EVERY time without fail. Nowadays, on the rare occasion that I might duplicate a model part for a project, I still use it and it still works. Very inexpensive too, I might add! Art

-

AMT Trophy Kits Out Now May 2018

Art Anderson replied to regular guy's topic in Car Kit News & Reviews

A '58 Ford Pickup? Hmmmm, interesting given that AMT made just the last model year of that style F-100, the 1960, and that kit hasn't seen the inside of an injection molder since perhaps early summer of 1960. Art -

Drills For Plastic (making holes!)

Art Anderson replied to Miatatom's topic in Model Building Questions and Answers

They are very nice, and very sharp, but be advised that they DO NOT work at all well in a hand-rotated pin vise, as tungsten carbide is extremely brittle; the slightest flexing will break them. Now, if one has a truly precise miniature drill press, they do work well (a HS classmate of mine develops custom printed circuit boards on the side, uses them a lot). Art -

Drills For Plastic (making holes!)

Art Anderson replied to Miatatom's topic in Model Building Questions and Answers

Another, and more durable type of small (tiny) drill bits, that are quite sharp, but have a very strong shank, is what's called a "center" or "centerline" drill. This type of drill bit comes with a 1/8" shank, with the outer end sharply tapered, down to the desired drill bit diameter. The drill bit portion is generally about 3/64" inch long. Most of the ones I've got are made in high speed steel, and are actually quite durable--plus the 8th inch shank fits perfectly in the larger 1/8" Dremel collet (also works well in the Jacobs chuck I often fit into my Sherline vertical mill. Art -

The only problem I see is if the liquid glue-dissolved styrene "putty" causes the outside surface (top) of the hood to settle and shrink, given that the hood panel is quite thin on the exterior surface from the grooves molded to the underside. I've used gap-filling CA glue with accelerator to fill those cutout groove guidelines over the years, with great success. Art

-

The original 1969-issued kits of the STP Lotus Turbine, Rislone Eagle-Offy, and the Gurney Eagle-Ford/Weslake all had the Wheelhorse tractor, which in those days was the "Official" tow tractors used in the pits and to and from Gasoline Alley at Indianapolis to move race cars around. I suspect that licensing issues are what eliminated those little tractors from these kits. Art

-

Model Car Wikipedia style

Art Anderson replied to Spruslayer's topic in General Automotive Talk (Trucks and Cars)

Interesting read, pretty accurate too, but typical of most Wikepedia articles, a bit sketchy. -

Revell 57 Ford wagon question

Art Anderson replied to thatz4u's topic in Model Building Questions and Answers

A '57 Ford Courier Sedan Delivery should be a breeze, off the Del Rio! For the body shell (and tailgate/liftgate), the conversion is very simple: Note that Ford did two distinctly different bodies though, with regard to the long side (quarter window area): While the standard Courier used a flush-fitted sheet metal upper rear quarter panel (with just a hint of the upper B-post in the surface behind the side doors), they also did a distinct version for the US Post Office Department: This one had the same window openings as the Del Rio, but with just a single pane of Safety Plate glass in them, that did NOT slide open. Apparently, Ford also ran some Couriers for general sale alongside the Post Office version, which did have the window opening, but not cut open for glass--making for a recessed upper rear quarter, which would be even easier to do off the Del Rio--just a piece of say, .020" Evergreen sheet styrene laid on from the inside of the body shell. The other body modification would be to the tailgate. While Ford station wagons used a split "Lift Gate-Drop Gate" unit (just as did every other US automaker back then), in order to reinforce the lift gate, Ford divided the rear glass into three sections, with framing members mounted vertically, in alignment with the upper hinges--and a second "tee shaped" handle in the middle of the lower portion of the lift gate, which also served to lock it. Inside, the rear floor was extended all the way to the B-post, with access lids for the spare tire (at the very rear), and where the second seat of the Del Rio would have been, a pair of plywood "lids" that served to provide not only the extended load floor, but were hinged down the center line with recessed handles for lifting them up (for the discreet loading of possibly valuable cargo). This is an ex-USPO Courier, with full side windows: https://www.google.com/search?q=1957+Ford+Courier&source=lnms&tbm=isch&sa=X&ved=0ahUKEwip47Ll6-_bAhXWGDQIHaWiCBQQ_AUICigB&biw=1920&bih=974#imgrc=ieV6D08EVZjodM: Standard, flush-sided version--look carefully, you can see the hint of the B-post in the upper quarter panel (note though that Fairlane trim likely was added to this one when it was being restored--never have seen any that were like that when new. https://rmsothebys.com/en/auctions/HF14/Hershey/lots/r224-1957-ford-courier-sedan-delivery/182038 Also, stock as built, these had single separate front "bucket type" seats, with the passenger seat made to fold down, then forward, for ease of access to the cargo area from the side door. Art -

Hobby Lobby sells many brands, types, and levels of quality brushes--if you can stand the extra price, it's pretty hard to top the Winsor & Newton brand--very top quality sable, and in sizes and styles that more than fit any model builder's needs. Also, take a look at Grumbacher (HL carries those as well). Both brands cater to artists and serious craft persons--I've found both to be excellent. Art

-

When I moved my considerable stash back here to Lafayette from Mishawaka IN (next door to South Bend), I took the mindset that model kits are delivered in cartons of a dozen (generally), in which the kits fit snugly (but not forced into the cartons!). With that in mind, I went to a Walmart, and to my surprise, found a size carton that fit those standard AMT model kits perfectly--the key here is to locate cartons that do just that. There are even cartons out there that will hold, very securely, upwards of 20 standard AMT/MPC kits very nicely. As for moving my builtups, I have found that for most all 1/25 scale model cars, those that are 50's and later models, 550-count baseball card boxes work quite well--in fact, those are what I use to transport models to and from model car shows, even carry them in a cloth tote when traveling by airline (carry-on baggage). As a thought, if you need a lot of such cartons, once you find the size that works as I've described, go online to U-Line's website, as more than likely they have exactly the same size, but in bulk, and priced quite reasonably, and U-Line ships those out in standard bundles, very quickly. Art

-

74' Turbo Offy specs?

Art Anderson replied to aurfalien's topic in Model Building Questions and Answers

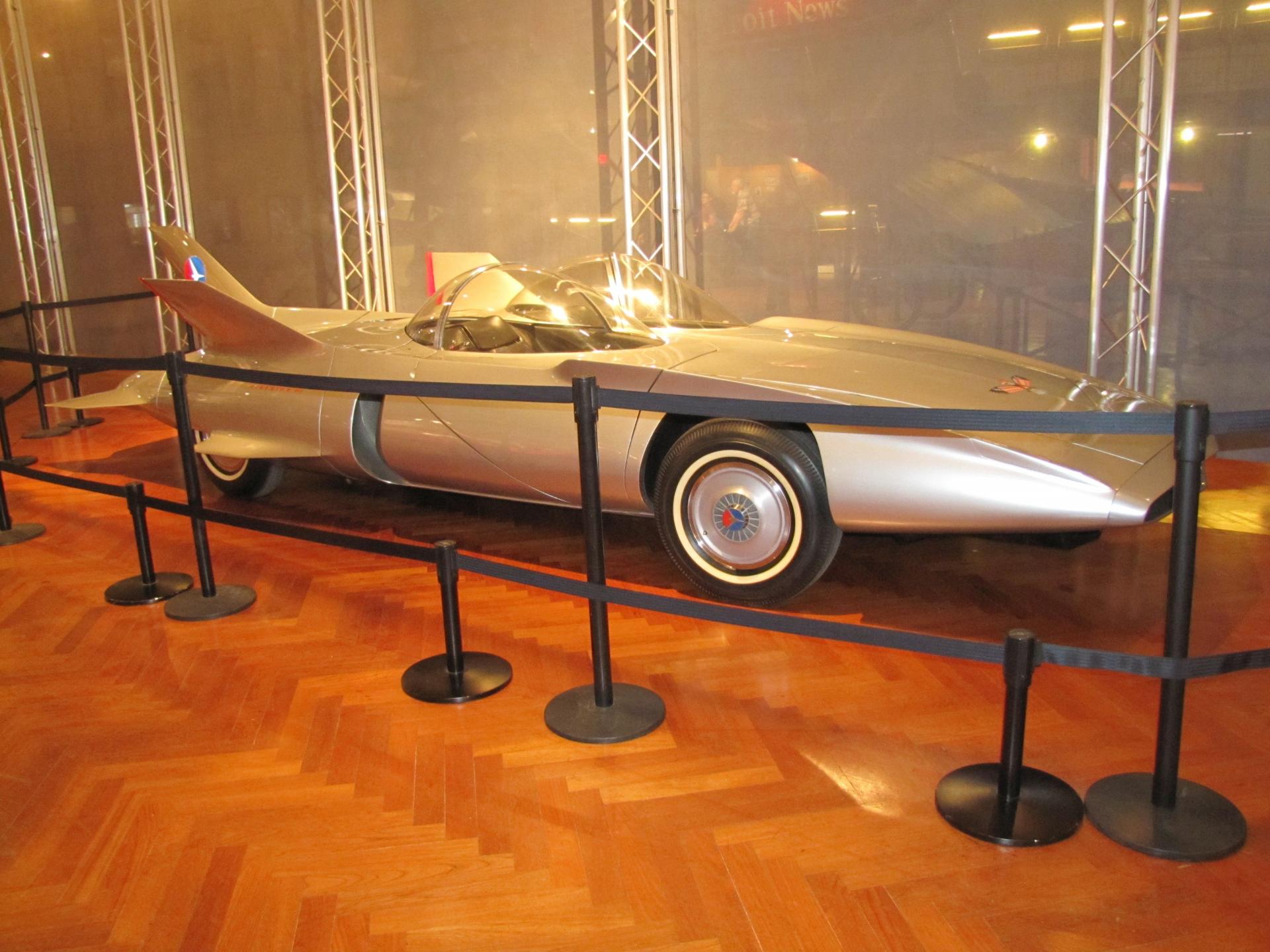

I said Underslung, but that was the way turbochargers had been set up on Offies from 1968 forward. On the 1974 M-16c Mclarens, in order to lower the center of gravity a fair bit (those turborchargers are actually quite heavy), they decided to mount the turbo "overslung", that is, with the hot exhaust gas inlet being above the body of the turbocharger, which placed the unit directly in between the rear of the cam towers and the framing for the rear suspension, so that 10" extension "collar" was designed, and machined in forged aluminum to give the needed space. To trim as much weight as possible, a fair amount of metal was milled away on the outside, between the bolts holding it to both the Offy flywheel housing, and the suspension bulkhead (remember, with McLaren, as with the Eagle Model 6, the engine and transaxle served as a part of the chassis, bearing the weight, torque reaction, and the stresses of corning speeds at the Indianapolis Motor Speedway, where lap speeds were approaching the 200-miles per hour milestone. Those Turbo-Offy engines were overall a charcoal grey metallic in color, with the cam covers being the same color (still raw cast iron & cast aluminum, with the finned crankcase side cover plates, and the water jacket covers being raw cast aluminum. On the tub, for 1974 and onward, USAC mandated just 60-gallon fuel capacity, and eliminated the right side fuel tank altogether, requiring that space to be filled with an energy-absorbing material, and on the actual car, just one fuel filler plug, and that appears on the left side of what on the model kit, is molded as if it were merely a head-rest (in reality, that was the so-called "seat tank", to which an electric fuel pump pushed the ethanol fuel from the left side fuel tank. What AMT made, and look like fuel filler plugs that they engineered to be glued to the outside of the left side of the tub, In reality, slightly recessed aluminum plates, black anodized, which were the access points for inserting the puncture-proof rubber fuel "bladder" into the box-section monocoque chassis sides (left from 1974 onward, on both sides on the McLaren M-16's from their introduction in 1972 through the disastrous 500 mile race of 1973. A review of the numerous photo's of this car, and it's 1975 successor, can guide you to the correct shape and length of the nose cone, and also the much narrower rear wing (AMT did this one as a cheaply done follow-on to their 1973 McLarens (the ones in Penske Sunoco colors), which is pretty far off. This is a very good walk-around video of the actual car, which is now part of the Indianapolis Motor Speedway Hall of Fame Museum collection Art -

74' Turbo Offy specs?

Art Anderson replied to aurfalien's topic in Model Building Questions and Answers

Brian, from my Indy Car modeling days (and 1974 was right in the middle of that), the Turbo in the AMT Mclaren kits is pretty danged close, if not spot-on, to scale. Of course, for 1974, the Mclaren M16D Indy Car had a 10" extension collar between the engine and the transaxle, which provided clearance for that "underslung" turbocharger, which does make a difference--an easy part to make and install. Art -

Revell 57 Ford wagon question

Art Anderson replied to thatz4u's topic in Model Building Questions and Answers

Mark, I would not discount the idea that Revell-Germany, once all the mess gets straightened out, does a Ranchero version--in fact I am willing to bet that probably most, if not all, the basic work (cad files, etc., may well even exist--but no direct knowledge of that, of course) Art -

Revell 57 Ford wagon question

Art Anderson replied to thatz4u's topic in Model Building Questions and Answers

In real life, the Ranchero was a version of Ford's 2dr station wagon, so that conversion should not be all that difficult. In fact, on the real Ranchero, the inner panels of the pickup box area are simply the stock station wagon steel inner panels, even down to the inside of the tailgate. All you should need to buy extra, would be some fluted Evergreen styrene, with at least close to the correct spacing, and the back cab wall part from any of the Revell '57 Ranchero's---although ever since the middle 1960's that kit had a chopped top, but stretching the upper part of that back panel isn't exactly rocket science! Art