-

Posts

4,608 -

Joined

-

Last visited

Force's Achievements

MCM Ohana (6/6)

-

That will be quite a chore. First you have to have a 3D scanner and a 3D printer, scan the parts from a kit and do print files from the scans, and then print them out, the Revell Peterbilt Can-Do/Will-Do wrecker has about 650 individual parts and the Revell Kenworth K100 kits somewhere around 300-350, so it's time consuming and most likely expensive to do a complete 3D printed kit of these. Revell still have the tooling for these kits so they will most likely come out again sometime.

-

Issue 226 is On Its Way

Force replied to Dave Ambrose's topic in Model Cars Magazine News and Discussions

Model Roundup sells the magazine. -

The instrucktions for both are the same except for the decals. The kits are slightly different from the original kits from 1984 tho' as the kits were altered for the later Pontiac Firebird Pro Stock bodies from 1991-92 and again for the 1999 Firebird kits, all are based on the same tooling from 1984. So some things are different, the most obvious things are the bodies and wheels, the roll cage is slightly altered with a Funny Car style cage around the drivers head wich the originals didn't have, the rear wheel wells are modified some to fit the later Firebird bodies, the valve covers are different as the newer kits has welded sheet metal valve covers and the original versions had casted Moroso covers, the intake manifold is also different as the later one has the runners covered with sheet metal. If you get hold of the Tony Foti L.A.P.D. version from 1991 the engine has a blower and you get a light bar for the roof, otherwise it's pretty much the same as the 1991 Pontiac Firebird kits except the body is a Camaro.

-

One thing that make me doubtful that it's the same car is the time factor, they did the first race with the SS/E car in April and I know they supposed to have raced it at Indy in the SS/E configuration, they rebuilt the car and put on the vinyl top and raced it in C/MP for a number of races, and finally sold the car at the end of the season according to the Sox & Martin book and built the 1971 Road Runner for B/MP. So they couldn't have used the Superbird much in either SS/E or C/MP configuration. The book doesn't mention the C/MP car, just the SS/E car.

-

Well a Top Fuel kit doesn't have to be all new, just some updates to the last version wich isn't that much to do it like the current dragsters. Slightly modified chassis with a new roll cage and head shield, modify the body slightly with a larger wind shield or do a new one with the DRS canopy and to the front to do the one piece front wing and a belly pan, do some updating to the engine with new larger magnetos, a set back blower, new fuel pumps and new valve covers with spark plug shields, and finally change the rear wing to a 3 element...and you will be pretty much done. Wheels changes all the time but not as often than they have been in the past.

-

The Revell tool for the Don Garlits Swamp Rat XXX was appearently sold to Atlantis is they recently isued it, and so are the first "modern era" Funny Car tool as they are releasing the Don Snake Prudhomme old Pepsi/Wendy's Pontiac as the Pepsi Challenger Pontiac, and all the later Funny Car kits are based on this tool. I don't know if all the Revell Top Fuel tooling ended up with Atlantis or if it was only the Swamp Rat XXX...time will tell.

-

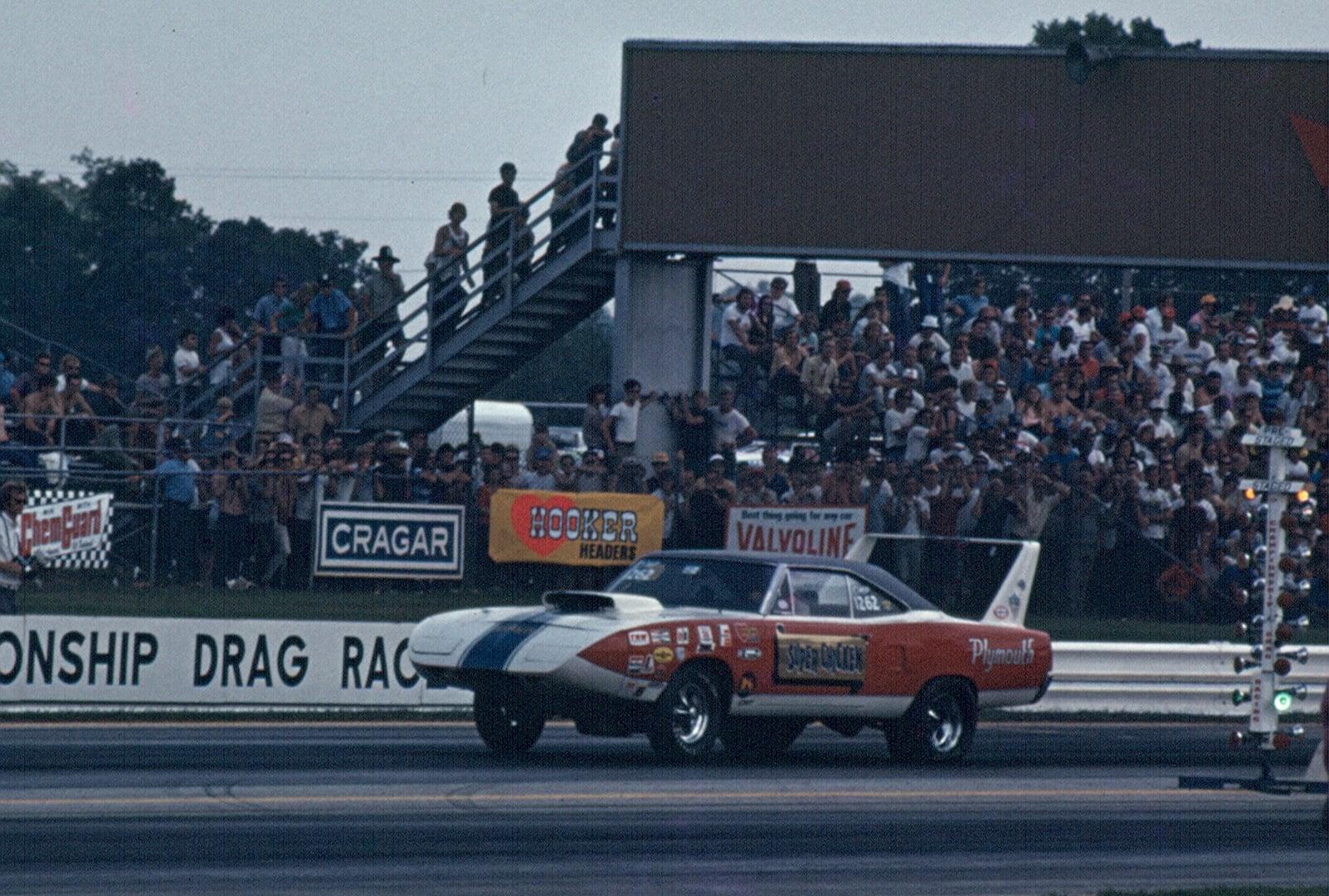

Here is an under hood picture of the C/MP ERTL Supercar Collectibles 1/18 die cast car, I don't know how accurate it is tho' as I haven't found any picture of the engine in the real C/MP car. The C/MP car was appearently sold after the 1970 season and ended up as the "Super Chicken" and this picture is from Indy 1971, the first race with the SS/E car was according to the Sox & Martin book in the beginning of April 1970 so if the SS/E and C/MP cars are the same car they must have rebuilt it quite soon to the C/MP configuration..and why they put on the black vinyl top is confusing as the SS/E car didn't have it. I also read somewhere that the Superbird was lost to a fire, but that an be a rumour, but it has gone throught my head.

-

The C/MP car appearently had a tunnel ram style pretty much like the 1970 'Cuda, at least from the pictures I have seen...but they could have tested several intakes on the car, MP stands for Modified Production and had looser rules. I don't know if there has been confirmed that the SS/E and C/MP car was the same car, it could be but I'm not sure as I have not seen any confirmation of that...and why would they put on a black vinyl top on the car when it didn't have it when it was ran in Super Stock...so it's confusing but it doesn't matter tho'. They only ran the SS/E car (and SS/EA car for Werst) for a short while as it wasn't really Super Stock legal and had lots of unapproved modifications to it, and the goal was to beat Ray Allen's Chevelle Convertible and then redlight or something in the next run so they wouldn't be checked after the race...that's the story I've read.

-

Just a tip, the front glass is the same for all Revell and Monogram 1965 and 1966 Mustang Fastbacks and Shelbys, they are all from the same basic tooling.

-

The Budweiser King and ARMY dragsters was the last Top Fuel dragsters from Revell and they came 2002.

-

I personally don't like the 10 spoke wheels in these kits, they doesn't look right to me. The 10 spokes in the 1968 Shelby are even worse.

-

I have seen 3D printed ones...I don't remember where tho'.

-

The thing with Revell and their "modern era" Top Fuel kits is that the first one was Don Garlits Swamp Rat XXX in 1987 (now with Atlantis)...and that bit them in the tail end as that dragster was pretty much a one off and no other team followed on that one. So they had to start all over and do mostly everything new when they did the Gary Ormsby Castol GTX and Joe Amato Valvoline dragsters in 1991 and they plus the following kits in 1992, the Lori Johns Jolly Rancher and Tom McEwen Mobil 1 dragsters, were very accurate, after that even tho' they did some updates, they fell behind more and more and could never really catch up. With the Funny Car kits wich first was introduced under the Monogram brand they based all the "modern era" kits on the Don Prudhomme Pepsi/Wendy's Pontiac, Dale Pulde Miller Warrior Pontiac and Billy Meyer's Chief Auto Parts/7-Eleven Mustang from 1985, so they all have the same basic chassie and engine from that time with some small updates, and new bodies as they changed over the years, and same here, they did updates but never enough to catch up.